As an LED manufacturer exclusively serving the electric sign industry, we are constantly evaluating our material costs with both distributors and sign companies. I regularly hear about tightening margins, and typically the finger pointing goes back to the easiest target—material suppliers.

作为专门服务于电子标识行业的LED生产商,我们时常与经销商和标识公司分析材料成本。我常常听到有人说,标识行业的利润出现紧缩的现象,随后他们就通过降低材料成本来提高利润,因为这是最容易实现的渠道。

My friends who manufacture plastic, metal, paint, and film tend to agree. When I travel to different sign shops, I hear each of them tell me about how“competitive”their market is, as if somewhere there must be some Garden of Eden where there are no price pressures.

我有一些生产塑料、金属、油漆和薄膜的朋友也赞成这种做法。当我走进不同的标识商铺时,他们每个人都在说,他们所处的市场竞争有多么激烈,好像其他地方都像是伊甸园一样,根本不存在价格竞争压力。

Material providers have become the magic bullet for sign companies to improve gross profits and often purchasing managers play manufacturer and distributor against one another. While this approach may generate profits in the short term, I do not believe it will produce sustainable results. In fact I suggest that it may be harmful to the long-term health of our industry.

目前,材料供应商已经成为标识公司提高利润的有力武器,采购经理经常要跟制作商和经销商进行谈判。这种方式在短时间内可能会创造利润,但是我认为它不是长久之计。事实上,我推测它很有可能损害标识行业的发展。

Evils of Price Erosion

价格下降的罪魁祸首

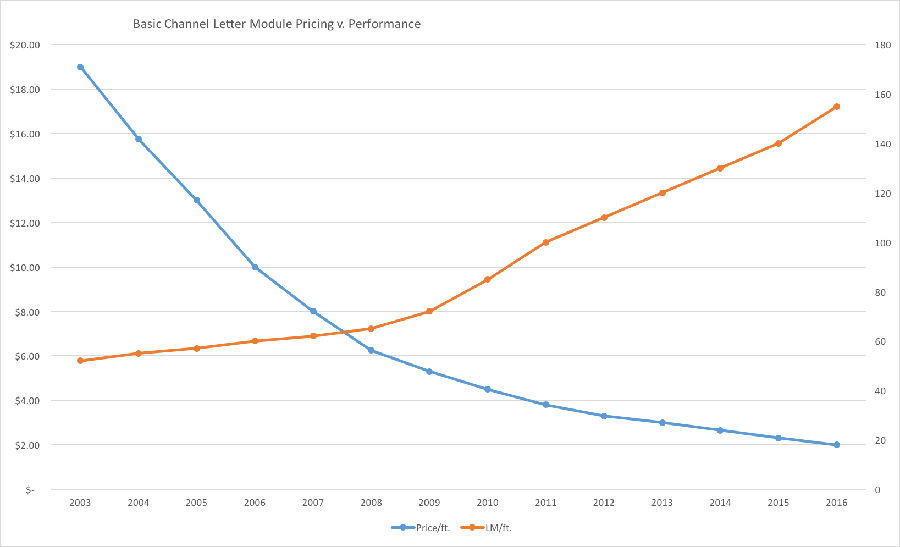

No one knows what price erosion feels like more than those of us who have manufactured LEDs for signs over the past decade. In ten years, we have seen the performance of LED modules double or triple, while average sales price has eroded by eighty-plus percent. While this is primarily a function of the semiconductor industry, it is not typical for other more commoditized sign materials.

在过去十年里,没有人比我们更加了解什么是价格下降,因为是我们把LED融入到了标识制作中。十年里,我们看到了双重或三重LED模组的性能,然而它们的平均销售价格却降低了超过80%。虽然在半导体行业中,LED的价格本身并不高,但是作为更加商品化的标识制作材料,这样的价格就有点过低了。

Imagine, as a sign manufacturer, if the same 4’x 8’double-sided monument sign that you were selling in 2005 for $5,500, you sold today for $750. That is exactly what has happened in the LED sign module business. In order to do this, you would likely have to cut corners—from materials to less skilled labor to lower margins. The fact is that we have started down a viscous path that I believe may hurt our industry in the long term if we don't start thinking differently.

想象一下,作为一个标识制作商,如果是同样的4’x8’的双面纪念碑标识,在2005年售价是5500美元,而今天售价只有750美元。这样的差别就相当于LED标识模组行业所面临的价格挑战。为了提高利润,你可能就会通过减少材料成本或削减劳动力来降低成本。事实上,从长远发展来看,如果我们不采取其他措施的话,这样的做法就会阻碍公司的发展。

Pricing Pressures

价格压力

People often ask me where the bottom is for LEDs. Figure 1 tells the story clearly. Prices have started to bottom; however, module brightness has continued to advance thanks in part to our big brothers in the general lighting market. The LEDs inside of the module now only cost about 20 percent of the total manufacturing cost of a module, with the rest being VHB tape, plastic housings, lenses, PCB material, wire, other electric components, and freight costs.

人们总是问我LED最低成本是多少。从图一中可以清楚地看到,LED的价格已经降到最低了,然而,多亏了照明市场中其他设备的发展,照明模组才能不断地在发展进步。照明模组中的LED,目前的成本只有整个模组成本的20%,其余的成本包括VHB胶带、塑料外壳、透镜、PCB材料、电线、其他电子元件和运费。

This will create an interesting scenario where at some point no more light is needed, as signs are more about distributed light than bright point sources as in general lighting (we will explore this later). Regardless, this scenario means that further cost cutting comes at a price and LED manufacturers only have two levers—reduce services or cut corners on materials.

这样就会产生一种有趣的现象,标识更倾向于分散式照明而不是整体照明方式。而这就意味着,进一步降低成本是必然的,并且LED制作商只有两个选择——减少LED应用或在材料上偷工减料。

Low barriers to entry in the generic module business have compounded LED price pressures. In fact, just the other day one of our estimators was called for a layout request using one of our sign modules. When the estimator suggested a better option, the sign company went on to explain that he wanted to use the module he requested because it was closest to the specifications of a low-cost competitor's LED module he had already purchased and since they did not offer these services, he wanted us to do a layout so he could get a good module count. Wow! Talk about brazen.

照明模组行业面临的小障碍就是LED价格方面的压力。我们公司的一个评估分析师最近接到一个请求,对方想要用我们公司的其中一种标识模组做出整体布局方案。当分析师提供了一个较好的方案时,这家标识公司并不满意,他想要用他已经购买的低价格的LED模组最接近的预算,让分析师为其做出一个合理价格的布局方案。

Every day I hear about“LED suppliers”that have not even been in business a year, with no office or support in the USA, offering long warranties and modules at rock bottom prices. What is worse, I see sign companies putting their reputations on the line to save $50 on a set of channel letters. A $500 service call alone will not only wipe out the savings but likely all of the profit on the job—not to mention a tarnished reputation. Fundamentally, I believe that sign makers know this is bad business, but current macro-economic conditions have been driving this behavior.

我发现目前有很多所谓的“LED供应商”,他们进入该行业甚至还未满一年,在美国也没有办公地点,而且还以最低的价格销售照明模组。更糟糕的是,很多标识公司竟然不顾其声誉,只为了在槽型发光字方面节省50美元。一个500美元的独立项目不仅会消除节省下来的钱财,还可能造成利润亏损,更不要说名誉受损了。从根本上来说,我相信标识制作商能够意识到这不是一个好现象,但是目前的宏观经济条件却推动了这种势头的发展。

Taking a Hard Look

认真审视自我

I have felt for some time that we needed to approach this problem differently; so at my company, we decided to take a hard look at who we are and what we believe. And I know other reputable LED manufacturers have done the same. Our belief is that we as a manufacturer exist to help make our customer’s lives simpler, and we've found that many sign shops are time and resource poor.

我思虑已久,我认为我们需要换一种思维来看待这个问题。我们需要仔细审视一个问题:我们是谁,我们坚持的是什么。我了解到,一些有名气的LED生产商已经做过了同样的事情。我们的宗旨是:要成为让客户生活更便捷的标识制作商,并且我们发现许多标识商铺在时间和资源上是很匮乏的。

So instead of lowering prices or cutting corners on materials we went back to the drawing board and decided that we should only create products that were a representation of what we believe. This was a big bet, but the results have been remarkable.

我们应该只做我们始终坚持的优质产品,而不是通过降低价格或在材料上偷工减料来提高利润的劣质产品。这或许是一个大的赌注,但是结果是值得的。

Here is the simple LED-lit sign analysis that drove our decision to change how we innovate (keeping in mind that these numbers can change a lot depending on a wide range of variables):

这是一个简单的发光LED标识分析数据,也就是它才促使我们改变了想法,做出创新型产品(注意:这些数据会根据变量不同而呈现出不同的结果):

Summary Cost Analysis: 4' x 8' Double Sided LED Monument Sign

LEDs & Power Supplies

$700

16%

Metal/Plastic/Finish Materials

$1,300

30%

Fabrication/Installation

$1,800

41%

Engineering/Permitting

$300

7%

Equipment/Overhead

$300

7%

Total Manufacturing Costs

$4,400

100%

简要成本分析:4’x8’双面LED纪念碑标识

LED和电源供给

700美元

占比16%

金属/塑料/加工材料

1300美元

占比30%

制作/安装

1800美元

占比41%

设计/分配

300美元

占比7%

设备/开销

300美元

占比7%

总计制作成本

4400美元

占比100%

In this case reducing the LED costs by 20 percent only saves the sign maker 3 percent on the total job cost. The industry doesn't need cheaper products, it needs better, more innovative ones. If we could cut our customers labor and/or install time in half, we could sell something at twice the cost that still saves our customers in installation/labor costs—and maybe more importantly, save them time. With this simple idea we decided to initiate some experiments to see if the logic would bear out.

这样看来,降低LED成本的20%相当于只为标识制作商节省了总制作成本的3%。该行业不需要廉价的产品,只需要更好更新颖的产品。如果我们可以削减一半人力或安装时间的话,那么我们就能以两倍的成本价出售产品。带着这个想法,我们做了一些实验来验证该想法是否可行。

Three Experiments

三个实验

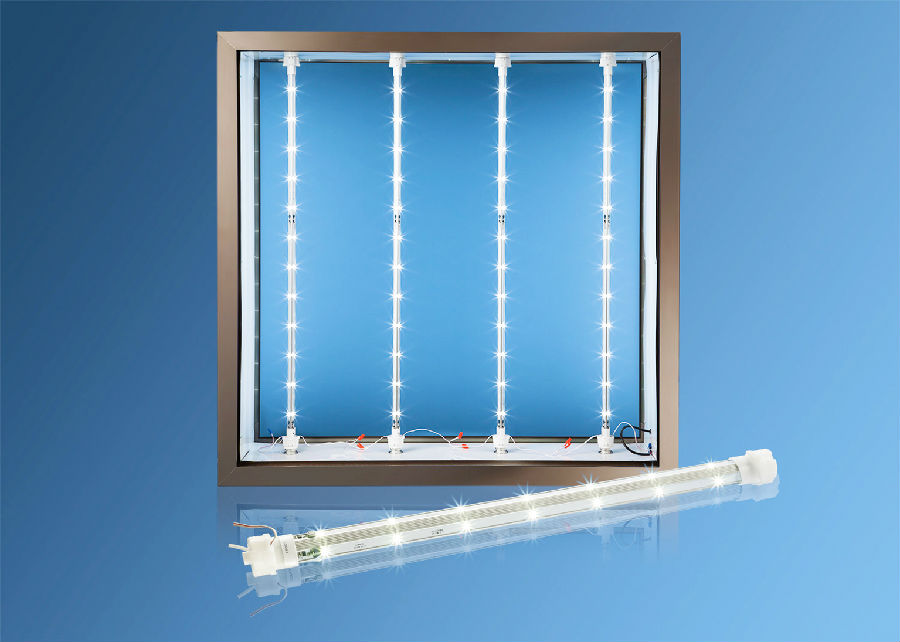

Our first experiment was aimed at the installation side—a pre-assembled LED product for retrofitting fluorescent lights in sign cabinets that we released in 2014. At the time, honestly, many people were skeptical. The prevailing thought was that sign companies “build stuff” and that no one would value pre-assembled LED sticks for the service side of the sign business. We hoped differently and after setting up a manufacturing operation in the USA, we began offering these units.

第一个实验是关于安装方面的。我们准备了新型荧光照明灯箱标识,这是我公司2014年推出的采用预先装配的LED模组制作的产品。当时很多人对此都持怀疑的态度。因为大家都认为,标识公司不可能使得预先装配的LED模组在标识行业发挥真正的价值。但是我们持相反的观点,并且在美国创立了生产公司之后,我们就开始做这个产品了。

Well, the product took off and since that time we have widened the range of T-12 products and other value-added assemblies. Today a large part our revenue comes from our assembly operation. We had begun to reinvent ourselves and how we thought about LED sign products.

从那时起,我们就拓宽了T-12产品和其他增值组件的应用领域。我公司目前的大部分利润都来自装配组件应用。我们开始彻底改造自身,真正深入了解LED标识产品。

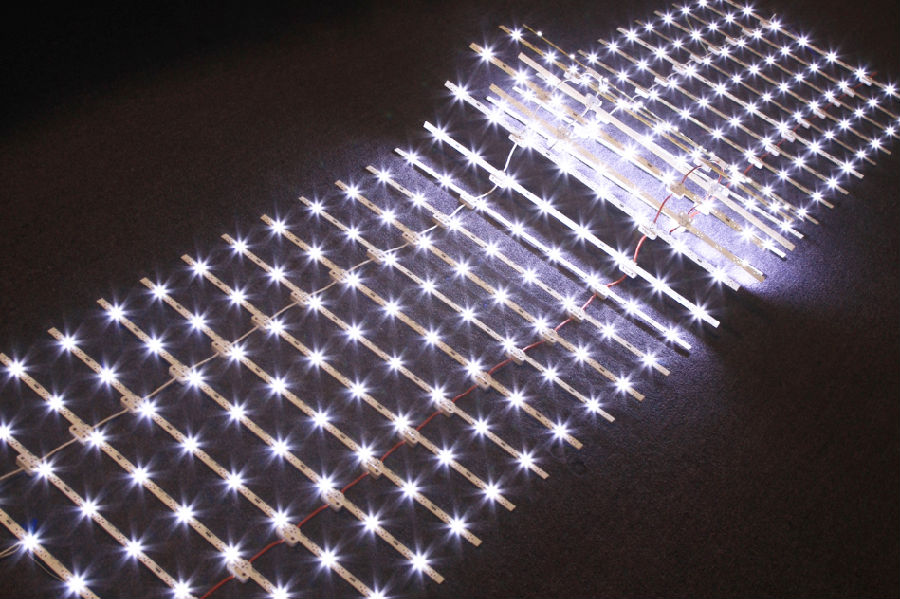

So we tried the experiment a second time, aiming now at new-sign construction. Remember earlier when I said that high brightness LED point source lighting has become affordable? The question then became, how do we distribute light more evenly at shallow depths? The result was a module product we released earlier this year that allows for even illumination over a wider area. The idea was that by spreading the light more evenly we could dramatically reduce a sign shop's manufacturing times and costs for large cabinets and cloud signs by reducing the number of modules needed for a given job.

我们开始第二个实验,是关于新型标识架构的。还记得我前面提到,高亮度LED点光源照明已经可以负担得起了吗?那么问题来了,我们如何均匀地分配深色区域的照明点呢?今年推出了一款LED模组产品,实现了更大区域的照明,解决了这个问题。通过均匀地分配照明点,我们可以大幅度降低标识商铺的制作时间和成本。

Needless to say, we sold out before the first 5,000 units hit our distributors' shelves. We really shouldn't have been surprised. It validated what we had learned from our first experiment—that sign shop owners are smart, they understand where their real costs are and they truly value time.

毋庸置疑,在首批5000件产品供给经销商之前,我们的产品已经全部卖完了。这就验证了第一个实验中我们的想法——标识商铺很聪明,他们知道真正的成本是什么,并且他们真的很珍惜时间。

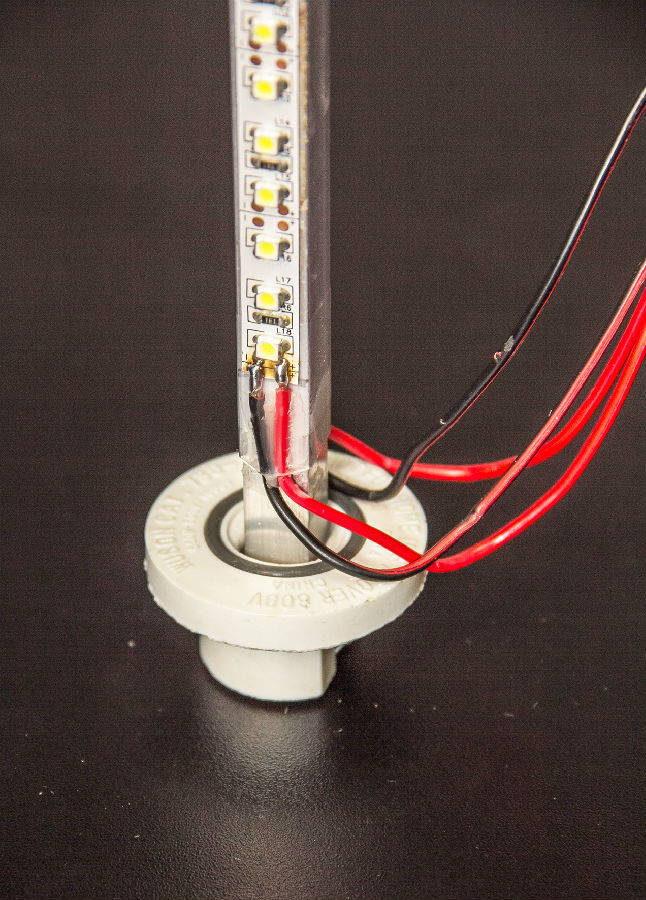

Now for experiment number three. Why not? We were are on a roll. As our team visited sign shops we realized they have thousands of LED modules on their shelves in various colors and brightness from a bunch of different manufacturers. This back stock represents a lot of tied up cash, and we thought to ourselves—If we can save time and help improve our customer's profits, why can't we help them free up cash by reducing their inventory?

现在开始进行第三个实验。当我们的团队拜访标识商铺时才发现,他们有成千上万种来自不同生产商的LED模组,包括各种颜色和亮度。在某种程度上,这些库存就意味着大量的资金占用。如果我们能做到节省时间,并帮客户提高利润,那么为何不能通过减少他们的存货来帮其缓解资金压力呢?

So we developed a unique LED sign module that is designed to be as versatile as possible. The idea is to have a single module can provide three different outputs (from 140-240 lumens per square foot) simply based on how it is wired. With its removable batwing optic, that one module can now be used for just about any sign with depths from 3.5"-18".

因此,我们制作了一个独特的通用型LED 标识模组,其原理就是单个模组根据接线方式不同可以供给三种不同的输出(每平方英尺140-240流明)。因其可移动的蝙蝠状镜片,该模组可以用于厚度范围在3.5"-18"的任何标识。

From a financial perspective, one module for multiple applications means less shop inventory, which means more freed up cash. We will wait and see how experiment number three pans out as we expect the product to be on our distributors' shelves sometime next month.

从财务角度分析,多功能模组意味着更少的库存,也就意味着有更多的可用资金。我们等着下个月见证第三个实验的结果,产品会否如我们期待的那样,在经销商那里停留一段时间。

Daryl Foreman, a sales manager at my firm with more than 37 years in the sign industry, recently reminded me that this way of thinking is not new to the sign industry. In the early 1980s Gerber introduced the Gerber Signmaker 4B, one of the first computerized plotters for cutting vinyl. It was way more expensive than hand lettering—retailing at around $17,000—but sign companies realized that they could quadruple their throughput, reduce scrap, and save tons on time and labor.

我公司的销售经理达利尔·福尔曼,在标识行业已经奋斗了37年,他最近跟我谈到,我的这个思维方式是标识行业创新型想法。在二十世纪八十年代早期,美国格柏公司推出Gerber Signmaker 4B,用来切割乙烯基的计算机化绘图仪之一。它比手工绘图昂贵的多,零售价大约17000美元。然而,标识公司意识到,他们可以得到输出量翻四倍的吞吐量、降低废品率并且节省时间和人力。

“I tell people all the time you should not to focus on cost per foot, but really evaluate your cost to use the product,” says Foreman.

福尔曼说:“我一直跟大家说,不要只关注每英尺的成本,而应该估量你的成本有多少可以用在产品上。”

Valuable Lesson

珍贵的一课

This is by no means an advertisement for my company. Other LED manufacturers are engaging in similar experiments and analysis. However, let's forget sales, profits and margins for a moment.

这绝对不是我公司做的广告。其他LED制作商也在做类似的实验和分析。不管怎样,让我们暂时先忘掉销售额和利润。

The lesson that I learned from these three“experiments”has been very valuable. What I learned is that we had to change our vista. We were hearing that sign companies want less expensive materials. But what sign makers really wanted was not lower prices—they wanted innovative products that make their lives simpler and saves time (which in turn saves money).

我从这三个试验中获得的经验是非常珍贵的。我们应该改变对未来的展望。我们知道标识公司想要更便宜的材料,但是标识制作商想要的却是让我们的生活变得更简单的创新型产品,并且能够节约时间的(在某种程度上也可以说是节约金钱)。

We have begun to apply this understanding to customer service, sales, and other areas of our business. I just wish we had done so earlier, but necessity I guess is truly the mother of invention.

我们已经开始把这种理念融入到了客户服务、销售额还有公司贸易等其他方面。

I acknowledge that this is not a traditional article, but I really wanted to share what I have learned. I believe that this formula can be applied to your sign business as well. My hope is that suppliers, distributors, and sign makers all continue to innovate and cooperate so that together we can all grow and continue to provide innovative, quality illuminated signs for years to come.

我知道大家以往或许也看过类似的文章,但是我确实很想分享一下我的经验。我相信这个经验能够很好地应用到你的标识生意中。我的期望就是,供应商、经销商和标识制作商能够继续创新合作,这样我们就能共同成长,以后继续制做出创新型、高质量的照明标识。