Client expectations are met with precision laser engraving.

激光雕刻的精准性能很好地满足客户对标识的高期望。

Laser engraving isn’t only precise; it’s fast. In fact, the whole industry is making improvements along its supply chain at rapid speeds. Because of this, designers, fabricators and artists can all now suggest signage concepts that just a few years ago would have been nearly impossible to produce.

激光雕刻不仅精准性高,速度也比传统的雕刻机器要快得多,事实上,近些年来整个标识行业都在因为激光雕刻而改善供应链,由于这项技术的出现以及逐渐成熟,现在无论是设计师、制造商还是艺术家,都可以独立进行标识的概念设计与制作,这在几年以前是绝对不可能的。

Some shops have been able to keep up, while others have moved on. For these three shops, being on the cutting-edge of laser-engraving technology has been a carnival of creative projects.

在这样的趋势下,一些标识作坊已经完成激光雕刻的转型,转而向更广泛的应用领域迈进;另一些则仍在延续之前的雕刻机器。

对于本篇文章中的三家标识公司/作坊来说,领先于行业的激光雕刻技术让他们在日渐增多的创意标识项目上,抢占了极大的先机。

MAIDS OF MARDI GRAS

狂欢盛典

Year over year, the Mardi Gras celebration tries to one-up itself. From the huge, decorated floats and the grand costumes of participants and parade-goers to the smaller elements like the quantity and quality of beads thrown to the hundreds of side parties taking place along the way, the only constant is the need to be bigger and better than last year.

年复一年的狂欢节不断试图制造新颖的元素,从巨大的装饰彩车到参与盛会的游行者们的华丽盛装,再到细节处的装点元素:比如在游街聚会时沿途抛掷的小珠子等等···每年的狂欢节唯一不变的就是变化,而且需要更大更好的变化。

This notion is something with which All Signs Inc. (Gulfport, MS) is familiar. Located in the heart of Mardi Gras country, they are often tasked by the Gulf Coast Carnival Association (GCCA) with creating signs for the maids and dukes of Mardi Gras. “Every year we do different types of signage for the participants,” All Signs Owner/President Michael G. Hage said. “The signs are used mainly for decorations in hotel rooms. They have a ‘party floor’ and every maid and duke has their own room and they transform these ordinary hotel rooms into elaborate party rooms for five days. Every year it seems like the decorations get more and more elaborate...this year’s krewe will have to outdo last year’s krewe.”

All signs公司对于狂欢节的概念非常熟悉,因为这间公司就位于密西西比州的加佛港,是狂欢节庆典国度的中心地带,每年都会受到墨西哥湾狂欢节协会的邀请与委托,为狂欢节的女王与公爵创建标识。

All signs公司的总裁迈克尔·哈奇说:“每年我们都会为狂欢节的参与者们提供不同类型的标识标牌,主要用于酒店房间的装饰,参与狂欢节的女王与公爵都有自己的专属房间,他们利用这些标识将普通的酒店房间改造成精致的宴会室并保持五天。这些装饰一年比一年的要求更高、更精致,今年必须要超过去年才能让人们满意。”

Even though the customer didn’t know what kind of sign they wanted when they approached All Signs, Hage said they usually go with laser engraved for the unique, dimensional look and ability to work in tons of details. The process of making the perfect sign for a maid or duke is pretty straightforward: The customer receives a conceptual bitmap rendering from GCCA that informs them of the theme for the year. All Signs then takes the rendering from conception to something usable that can create artwork using SAi Flexi Sign Pro design software. After proofing, the editing process and client approval, the final design heads into production.

尽管客户找到All Signs公司定制标牌时,基本都没有一个具体的想法,但是哈奇表示,因为有激光雕刻的帮助,很容易制作出具有独特的尺寸和外观并且细节丰富的产品,足以获得客户的肯定。而女王和公爵们的专属标识制作就更加简单了,客户会带来当年的狂欢节指定的主题特色,All Sign公司只需要用SAi Flexi Sign Pro设计软件将这些概念渲染为实际的图像,再重新设计优化一番并打样出来,经过客户批准后就可以量产了。

All Signs depends on their Trotec Speedy 300 45W laser for their engraving. Hage says they use vector-format art whenever possible, unless they have photographs, when they employ a bitmap format. The shop engraves using JobControl software.

All Signs公司进行激光雕刻的机器是Trotec Speedy 300 45W,雕刻软件则为JobControl,哈奇说,除非有现成的图像参考,否则在绝大部分情况下,他们都会选择使用矢量格式的艺术设计进行雕刻制作。

For this year’s maid and duke signs, All Signs used 3/16-in. Elmer’s foamboard because Hage likes the way it cuts (nice and clean) in the laser, and he also feels it accepts flatbed digital prints well. They also specified ORAFOL ORABOND double-sided banner hem tape to finish off the sides of the foamboard. The taped, double-sided elements were then aligned and adhered to each sign’s backgrounds. Finally, All Signs installed lights as needed, hot gluing them into place around the perimeter.

今年的狂欢节女王与公爵的标识招牌,统一标准为8/40厘米,在材料上哈奇选择了Elmer的发泡板,这种板材在进行激光雕刻时非常干净,没有太多的碎屑和粉尘,而且能够顺畅地进行平板印刷,另外搭配了ORAFOL ORABOND的双面横幅胶带作为标识侧边的包裹,并将其对应的双面图案对齐粘贴在标识的背景上,最后为它们安装照明灯具,以热粘合的方式固定在周边。

FORE SCORE

高尔夫奖章

When Nancy Stokes Hearn, owner of Stokes Sign Co. (Austin, TX) , sells clients on her shop’s laser-engraving capabilities, she focuses on their production value first and foremost. “The engravings have clean, precisely cut edges, allowing for more crisp and detailed lettering than other production methods,” she said. “We can help clients needing smaller sign applications with more elaborate logos and designs [and], because we laser engrave on-site, we offer faster turnaround time without sacrificing quality.”

Stokes Sign公司的老板南茜·海恩之所以选择激光雕刻作为标识产品的制作方法,是因为这种技术能够带来的产品价值非常高,她说:“利用激光雕刻制作的版画、标识,比其他生产方法的边缘更加清晰、精确,刻字也更精美。 此外还可以为需要较小标识标牌的客户提供更为精细的徽标设计,而且我们公司通常都是现场进行身缠,激光雕刻能够提供更快的周转时间并且保证质量。”

It was this known dedication to precision that led Erik Henson, head golf coach for nearby and long-time client Lake Travis High School, to approach Stokes with a general idea of the look and style he desired for the school’s golf wall of honor. “Once we were fully able to understand the client’s vision and the display parameters, we realized that this project was a perfect application for the laser engraver,” Marketing Manager and Graphic Artist Jenna Albright said. “The spatial considerations and the requirement to view the sign up close demanded a high-level production fidelity. This made using the laser engraver a natural choice.”

特拉维斯湖高中是Stokes Sign公司的长期客户,学校里的首席高尔夫球教练埃里克·亨森想要制作一面校内的高尔夫荣誉墙,并且对于这面墙的外观、风格均有很高的要求,他听说Stokes Sign公司一直以来都以精确性和执着追求著称,于是找上门来。

Stokes Sign公司的市场经理以及设计师珍娜·奥博睿特回忆该项目时说道:“当完全理解了埃里克·亨森对于这面荣誉墙所理想的视觉显示效果后,我们立刻意识到该项目完美匹配与激光雕刻机。这面墙壁既要保证空间占用,又要足够吸引人注意,同时还要高级的产品质感···综合这几点我想只有激光雕刻才能做到。”

Because Henson wanted to honor both team and individual efforts of players from the past, present and future, Stokes’ proposal included a series of laser-engraved name plaques adhered to acrylic photo displays with laser-cut, two-layered acrylic lettering above them. Although the Stokes design team was given creative freedom over the sign wall, there were other constraints. For example, the team had to determine how to incorporate traditional, digitally printed material (such as athlete photographs) into the final design. They also needed to take into account the sign’s overall weight by making the plaques as light as possible, since more would be added in the future.

亨森希望能够在荣誉墙上体现出:无论过去、现在还是将来,团队精神和个人努力都是球员们最重要的特质,因此Stokes Sign公司建议将一系列激光雕刻的名牌贴在照片外的亚克力板上,并在其上方用双层亚克力制作激光雕刻标牌。

尽管Stokes Sign的设计团队在荣誉墙的设计工作上获得了完全的创作自由,但是却收到了其他方面的限制,例如,团队必须考虑如何将传统的数字印刷照片无缝接入设计概念当中,另外还需要考虑荣誉墙牌匾的重量,因为将来墙上还会增加更多的标牌。

Ultimately, the Stokes team delivered a sign package that would scale with the golf program over time without sacrificing compositional balance, while incorporating design elements of the school’s brand for a cohesive look to fit other pre-existing signage. Albright said they used Photoshop to treat and edit the sign’s photos and SAi Flexi to marry the photos and vector elements together.

最终,Stokes Sign团队交付了一个整套的标识方案,该方案不仅考虑到现在的高尔夫荣誉墙的美观,也为以后继续增添标牌还能保持结构平衡做了预备,同时结合了学校的主体元素,以搭配原先已有的其他标识,使其更有凝聚力。

在制作过程中,珍娜及其团队使用Photoshop来处理和编辑标牌上的招牌,并用Sai Flexi软件将照片和矢量元素结合在一起。

To add dimension, the team used 1/16-in. Rowmark UltraGrave matte red/black engraving plastic and 1/16-in. Rowmark UltraGrave plus antique gold/black for the name plaques. The Stokes team mounted the plaques onto acrylic photo displays using 3M double-sided tape. The shop then reverse-printed the graphic onto the second surface of acrylic with their HP Scitex FB700 flatbed printer. They then flooded the printed side with white paint to both enhance the images’ colors and make them opaque.

为了保证足够的尺寸,设计团队使用了1.6毫米厚的Rowmark UltraGrave磨砂红与磨砂黑雕刻塑料,以及相同品牌、相同厚度的古董金色与古董黑色牌匾,依靠3M双面胶安装在亚克力板面上。随后使用HP Scitex FB700平板打印机将画面反向打印至第二层亚克力上,用白色涂料填充空隙,这样可以起到增强图像的色彩效果,并消除透明反光的作用。

The two-tiered, laser-cut, layered acrylic lettering above the award plaques was made from a solid sheet of 3/16-in. black acrylic overlaid with Avery Dennison brushed silver vinyl and attached to laser-cut, 3/16-in. red acrylic letters with 3M double-sided adhesive. All the pieces were mounted onto ¼-in. P95 frosted acrylic with silver, ½.-in. Pizazz Monomounts.

奖牌上方的双层激光雕刻亚克力文字由将近5毫米厚的实心板材制成,黑色亚克力上覆盖拉丝银乙烯基,然后与另一半同样5毫米厚的红色亚克力文字以3M双面胶贴合。剩下的所有零件都用6毫米厚的磨砂银色亚克力制作。

Finally, Stokes used a 36 x 24-in. Full Spectrum Pro-Series to laser-cut the double-layer acrylic lettering and engraved name plaques. Then, they employed RetinaEngrave and CorelDRAW to finalize the setup for cutting and engraving on the laser.

最后,Stokes Sign使用了90*60大小的双层亚克力制作最上方的标识牌匾,以RetinaEngrave和CorelDRAW软件进行激光雕刻机的工作设置。

IN PLANE SIGHT

慈善木墙

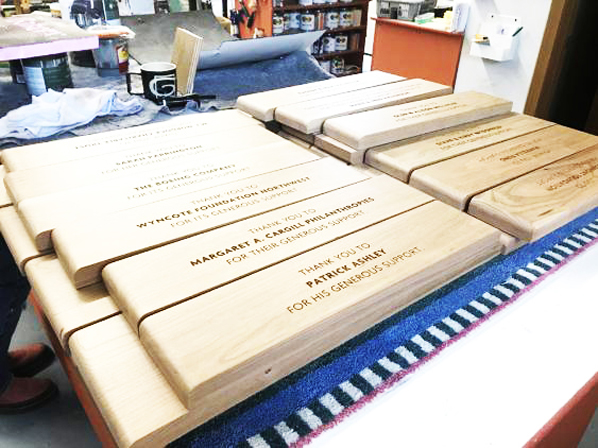

When the Burke Museum in Seattle needed a new donor wall, they called upon two companies to share in the project: Gibbs Graphics (Leavenworth, WA) and the Tube Art Group (Bellevue, WA) . While Tube Art handled the design and project management, Gibbs Graphics tackled the manufacturing and installation, according to co-owner Rusty Gibbs.

西雅图的伯克博物馆需要制作一堵新的捐助墙,并选择了两家公司共同参与项目,Gibbs平面设计公司负责具体的制造和安装,而Tube Art公司则负责设计和项目管理。

Initially, Gibbs said, they thought about creating the sign using a CNC router and fine-engraving v-bit, but soon realized a laser would be better suited for the job. “With a laser we would be able to have precision, speed and clean marks,” he said. “Also, the burn from the laser would make the letters darken and therefore eliminate the step of needing to stain or paint.”

Gibbs公司在接受项目的最初,打算采用传统的数控雕刻机以精细的锋线雕刻进行墙面上标牌的制作,但很快就意识到这个项目明显更适合于激光雕刻。因为使用激光雕刻,除了能够快速获得更精确更清晰的标牌外,激光的高温会自然使文字变暗,能够省去染色或上漆的步骤。

Although Gibbs said his customers appreciate the appearance of a laser-engraved wood sign, there were some difficult moments to conquer on the custom job before they reached the appreciation part. First off, several of the wood pieces were longer and larger than most lasers could fit. However, Gibbs’ Boss LS-1630 laser engraver had side doors that were opened to accommodate the long boards.

尽管Gibbs 将激光雕刻的效果说得很好,但在制作的过程中依然遇到了麻烦,比如组成捐助墙的一些木片,比激光雕刻机所能容纳的最大尺寸还要更长更大,好在Gibbs公司使用的Boss LS-1630型号的机器可以将侧门打开以容纳长木板。

While they were able to work the planks into the engraver, fitting them into the shop itself was another matter. “We needed to rearrange a bit to fit the 10-ft.-long boards,” Gibbs said. “Also, it was a bit of a puzzle to track each plaque through our production steps and prepare for a smooth installation because there were over 200 plaques and 35 different shapes and sizes.” Luckily, a smooth installation made up for the puzzle-like maneuvering of the pieces. After first putting up a 12 x 12-ft. wall, the team then covered that wall in ¾-in., planed cherry plywood. The individual, solid-cherry donor plaques were routed with an AXYZ CNC router to their own specific shape.

尽管能够将木板放进雕刻机中,但是这和能够进行生产却不是一回事,Gibbs公司的生产区域需要重新进行布置,才能放下3米长的木板并进行生产。此外,为组成捐助墙的每一块牌匾编号,为了后面的顺利安装而做准备也是一个难题,因为牌匾的总数超过200个,分别属于35种不同的形状和大小。

幸运的是,平滑的安装过程弥补了拼图的难题,他们首先安装好了一个3.6*3.6米的正方形面,然后安装团队用2厘米厚的刨光樱桃胶合板整个覆盖了捐助墙,最后用单独的胶合板用数控切割机制作为特定形状。

Vectric Aspire software was used to model the pieces for the router. Then, after the routing process, the team completed several levels of sanding before their Boss laser worked its magic. They also used the LaserWORKS software that came with their laser, Gibbs co-owner Amanda Gibbs said.

Gibbs公司使用Vectric Aspire软件,以及机器附带的LaserWORKS软件,作为雕刻建模的工具,在进行激光雕刻生产之前,安装团队还对木板进行了多层打磨。

The plywood sheets were hung with cleats and butted together dry with biscuit joints to keep them aligned. Gibbs Graphics used 3M VHB tape to attach the plaques to the plywood. “We all know that walls and floors are never plumb, vertical and square, but armed with detailed site visit notes this large puzzle went together like planned,” Rusty Gibbs said.

在安装时,先将胶合板粘连在防滑板上一起晾干,用饼干接头保持它们对齐,然后用3M VHB胶带将一片片板块粘贴到胶合板上。

公司老板鲁斯蒂·吉布斯说:“我们都知道墙壁和地板永远不可能保持完全的垂直,但是这个计划中的大难题总会随着我们的制作过程不断进行而到来,也会随着我们的制作过程不断解决。”