We could print you if we wanted to – in one piece,” Matt Cone of Cameron Advertising Displays (Camad) told me as he described his company’s 3D printing capabilities. Camad came to 3D printing as a large-format printer in search of a way to excite both new clients and existing ones. Titanic Design approached the technology from the perspective of a manufacturer. WhiteClouds started as a media company, but suddenly found themselves with clients looking for 3D-printed models. But no matter the journey, what I really wanted to know was: How will this innovation change the way we think about the business of visual communication?

卡梅隆广告展示公司的负责人马特·科恩说:“我们公司的3D打印技术已经非常成熟了,我们现在基本可以实现客户的任何打印要求。”卡梅隆广告展示公司凭借宽幅打印机进入3D打印领域。它最初是一家媒体公司,现在主要服务需要3D打印的客户,但无论未来如何,我真正想知道的是:这项创新将如何改变我们对视觉传播业务的看法?

The folks at Camad (Scarborough, ON, Canada) had been screenprinting for nearly 60 years and large-format digital imaging for nearly 15 when they were approached by Massivit 3D. “When we were being pitched, we probably sat there and scratched the backs of our heads,” said Vice President Dan Deveau, “but once we saw the press, we just knew.”

副总裁丹·德沃说:“加拿大斯卡伯勒卡梅隆广告展示公司的工作人员从事打印已有近60年的历史,而当Massivit 3D公司与他们进行接触时,他们已经使用了近15年的大格式数字成像技术。”

Cone wasn’t joking when he said they could print me in one piece. The Massivit 1800’s capabilities span up to 57 x 44 x 70 in. “It was a great opportunity to dive into something nobody else was doing,” said Cone. Camad began operating the Massivit in June 2018, but the learning curve was skyscraper steep. From beginning to end, 3D printing is just a different type of journey.

Massivit1800的打印高达57x44x70英寸。“它是一个很好的机会,可以深入到其他没有人做的事情上。 在2018年6月,卡梅隆广告展示公司开始运营Massivit,但这需要一个很长的学习过程。从开始到结束,3D打印只是一种不同类型的旅程。”

It starts with a sales call, of course, and according to Harky Aulak, account executive, “It’s a completely different sell.” In some cases, you’re calling on new business; in others, you’re having a new conversation with longtime clients. Often, your clients have to pitch the idea to their clients. “What it’s forced my sales guys to do is circle back,” Deveau said. “This is something that has to be nurtured and coddled and miniatures done; there’s a whole new conceptual thing that needs to be understood by all parties.”

主管哈基奥拉克说:“当然,我们从电话销售开始发展它。电话销售可以促进一些新的业务;同时,也可以通过电话销售与老客户保持联系,完善售后服务。通常,你必须向客户推销这个新型产业。我的销售人员要做的只是向客户传达这个新概念,当然你需要对工作人员进行培养,因为大家都需要理解这是一个全新的概念”

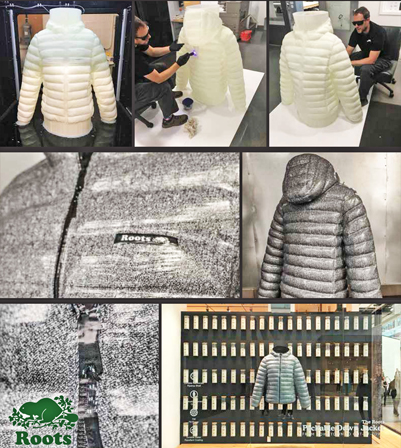

Camad 3D-printed this jacket for Roots, a nature-inspired clothing retailer in Canada.

So what makes all the back and forth, the patience and the intensive customer education worth it? “The wow factor,” said Cone. “Everyone that we presented to said, ‘Wow –could see us doing this,’ or ‘I could see us doing that.’”

卡梅隆广告展示公司的3d打印的这件夹克是为加拿大服装零售商Roots设计的。当科尼说:“在场的每个人都说这个3D打印真是棒极了,看到我们在做这个很惊讶。”客户的这些话让工作人员所有的劳累、艰难都变得值得。

The wow factor is just what Roots, a national retailer of nature-inspired clothing, was looking for when they said “yes” to a 3D project with Camad. The ask was simple: a 48 x 26 x 48-in. replica of a jacket. The production was straightforward, as well; Camad scanned the “real” jacket with a 3D scanner to create a 3D file. They printed it on the Massivit and then scanned the original jacket again for color. Camad then printed the solid color onto 3M Controltac IJ180Cv3 vinyl via an EFI VUTEk HS100 Pro and wrapped the 3D-printed model.

服装零售商Roots找到卡梅隆广告展示公司时,他们正在寻找的正是这种3D打印元素。这是一个48×26×48英寸,一件夹克的3D打印。制作过程也很简单,卡梅隆广告展示公司用3D扫描仪扫描真实的夹克,创建一个3D文件。他们把它印在大包装上,然后又扫描了一遍原来的夹克,看看有没有颜色。卡梅隆广告展示公司随后通过EFI VUTEk HS100 Pro将纯色打印到3M Controltac IJ180Cv3织物上,并给3d打印模型做了包装。

The jacket-model hung in Roots’ flagship store in Toronto’s Eaton Centre for a few weeks before Aulak received a call: “We sold out of those jackets. Can you take it down and re-wrap it in another color?”

这款夹克在多伦多伊顿中心的Roots旗舰店挂了几周后,奥拉克接到了一个电话:那些夹克已经卖完了。你能把3D模型拿下来,用另一种颜色重新包装吗?

“Well, absolutely,” Aulak said, so they scanned the jacket again, printed it red, and “up it went.”

“We can’t tell you that it’s the 3D jacket that made them sell out,” Aulak said, “but [they] certainly sold.” Roots has 180 locations around Canada – a new challenge for the Camad team.

“当然。”奥拉克说,于是他们又扫描了一遍那件夹克,把它印成了红色,然后就把它放上去了。奥拉克表示:“是3D夹克让它们卖光了,它们确实卖得很好。Roots在加拿大有180个地点,这对卡梅隆团队来说是一个新的挑战。”

ADAPTABLE IS EVERYTHING

适应一切

In 2019, the word “success” is often synonymous with “adaptable.”White Clouds

(Ogden, UT) is a prime example of adaptability. The business actually originated six years ago as a media company. The plan was to write articles and tutorials about 3D printing. WhiteClouds’ founders had experienced success with other media web properties; 3D printing was the cool new thing, and it seemed like a solid plan.

在2019年,“成功”一词与“适应性强”是不可分割的。白云公司是适应性强的一个主要例子。该公司是六年前成立的一家媒体公司,旨在撰写有关3D打印的文章和教程。白云公司的创始人在媒体网站上取得了成功;他们表示:“3D打印是一个很酷的新事物,看起来是一个靠谱的计划。”

But before long, folks discovered that WhiteClouds had a few 3D printers behind the scenes – a Maker-Bot Replicator and a 3D Systems Cube – and suddenly engineers and designers were coming to the company for print jobs. “We realized there was more of an opportunity in becoming a print shop versus a media company,” said Cris Fowers, who heads up WhiteClouds’ marketing and business development, and was a part of the company’s founding team.

但没过多久,白云公司就进了一系列的3D打印机——一个制造机器人的复制器和一个制作立方体3D机器。工程师和设计师们来到这家公司从事打印工作。负责白云公司营销和业务发展的克里斯福尔斯说:“我们意识到,相对于媒体公司,我们更有可能成为一家打印公司。”

WhiteClouds settled into a few niche industries: architectural modeling, medical modeling and the world of tradeshows and events. As they produced larger and larger pieces, they realized perhaps 3D printing works best in tandem with other manufacturing processes, and suddenly they had a woodshop complete with laser engravers, CNC machines, foam cutters and more.

白云公司进入了一些利基行业:建筑建模、医疗建模以及贸易展览和活动领域。当他们生产越来越大的产品时,他们意识到也许3D打印与其他制造工艺配合最好,于是他们有了一个木工作坊,里面有激光雕刻机、数控机床、泡沫切割机等等。

The welcome display for this year’s Consumer Electronics Show (CES) was a perfect example of different processes converging. Freeman, the company that manages CES, came to WhiteClouds with 2D artwork and a vision for a welcome display that would capture the spirit of the event and serve as the perfect selfie backdrop for attendees.

今年消费电子展(CES)的欢迎展示是不同元素融合的完美典范。管理CES的弗里曼公司带着2D艺术品和欢迎的展示来到了消费电子展,这种欢迎展示衬托了活动的氛围,为与会者提供完美的自拍背景。

WhiteClouds produced this welcome display for the 2019 Consumer Electronics Show.

白云公司为2019年消费电子展制作了一款受欢迎的显示器。

After formulating a plan that incorporated a 2D backdrop and a 3D display to accommodate the client’s budget, the Freeman and WhiteClouds teams set to work making 3D-ready files. WhiteClouds uses Autodesk Maya for prepress operations. The team elected to 3D print most of the figurines in the display – 11 pieces in total – with the exception of a game controller and the stage.

在制定了一个2D背景和3D显示后,Freeman和白云公司团队开始制作3D文件。白云公司使用Autodesk Maya进行打印前的设计,除了游戏控制器和舞台,该团队用3D打印大部分雕像。

It was no easy feat; the final display spanned 18 x 6 ft. and required eight weeks of production. WhiteClouds used Creality 3D printers with PLA plastic, and a MultiCam 1000 CNC router. Most pieces were sanded, primed, bonded, sanded again and airbrushed with Createx paint.

这并非易事,最终的显示器占地18 x 6英尺,需要8周的生产时间。白云公司使用Creality 3D打印机与PLA塑料,和一个麦迪克1000数控切割机。大多数工件都经过砂光、底漆、粘结剂、再砂光处理,最后喷涂了Createx涂料。

As for the decision to print some pieces and cut others out of foam, Fowers said the game controller seemed like a simpler shape that would’ve been more expensive to 3D-print. But after finishing was more tedious than expected, the team wondered if 3D printing would’ve been the more efficient way to go. “The one thing about our industry is pretty much everything we do is a one-off,” Fowers said. “We take our past experience and try to make good decisions.”

福尔斯说:“游戏控制器看起来更简单,3D打印成本更高。研究小组想知道3D打印是否会是一种更有效的方式。我们行业的一件事就是我们所做的一切都是一次性的,我们借鉴过去的经验,努力做出正确的决定。”

ONE PROBLEM AT A TIME

一次解决一个问题

Titanic Design (Mountain View, CA) is a large-scale 3D printing company established in 2016 when its founders saw a need for affordable 3D printing, particularly in the world of engineering. When I asked Tom Price, director of engineering and operations, what kind of clients a company like that serves, he said, “They have a problem that they need solved and they’ve heard 3D printing can help them.”

泰坦尼克设计公司是一家大型3D打印公司,成立于2016年,其创始人看到了3D打印的需求,尤其是在工程领域。当我问工程和运营总监汤姆•普莱斯,像这样的公司服务的是什么样的客户时,他说:“很多客户都表示经常有一个需要3D打印才能解决的东西。”

The problems Titanic has solved range from prototypes for groundbreaking sound-abatement technology to a 7.5-ft.-tall turbo fan engine to be used as a tradeshow prop. “3D printing is just another tool,” Price said. “The challenge is seeing where it works and where it doesn’t work.” He added that 3D printing, especially at this scale, is great for projects that are particularly unique, intricate or difficult to fabricate. Titanic commands a fleet of house-modified 3D Platform printers that can each churn out more than 35 cubic feet.

泰坦尼克号解决的问题包括从开创性的消声技术原型到7.5英尺高的涡轮风扇发动机,用作交易时的展示道具。普赖斯说:“3D打印只是另一种工具。面临的挑战是看它的工作原理。特别是在这种规模下的3D打印,对于特别复杂或难以制造的项目来说非常有用。 泰坦尼克团队拥有一系列3D平台打印机,每台打印机可以生产超过35立方英尺的产品。”

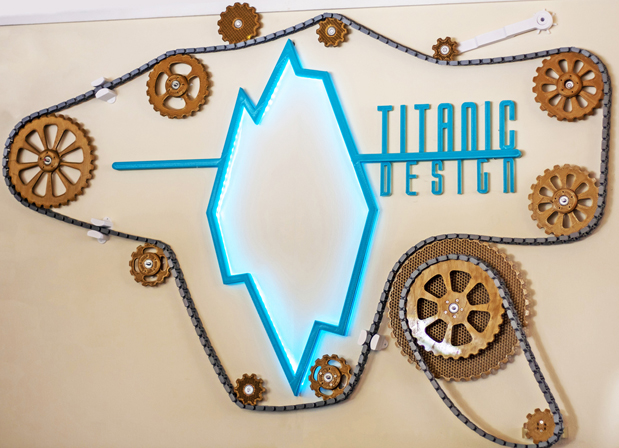

As for signage, the Titanic team decided to create a 3-ft., in-house display piece that would both test and show off their capabilities. “What would we be without a 3D-printed sign as a large-scale 3D printing company?” Price said.

至于标识,泰坦尼克团队决定制作一个3英尺高的标识。这款产品既可以测试,也可以展示它们的功能。作为一家大型3D打印公司,如果没有3D打印标识,我们会是什么样子?

The two-day job began with Titanic’s engineers adapting the company logo via Solidworks CAD software, but the plan wasn’t as simple as “print a logo and hang it up.” (It never is, is it?) The logo was engineered to print in two shell-like pieces in order to create a stand-out, backlit effect. The back piece is transparent and houses LEDs, and the front piece is teal. The sign looks as if it’s standing off the wall. Titanic used compostable, US-made bioplastic from Push Plastic.

这项为期两天的工作开始于泰坦尼克设计公司的工程师们通过Solidworks CAD软件修改公司标识,但这个计划并不像打印一个标识然后挂起来那么简单。为了创造一个突出的背光效果,标识被设计成两个贝壳状的部分。背面是透明的,内置是led,正面是蓝绿色。这个标识看起来好像是立在墙上的。泰坦尼克号使用的是可分解的美国制造的生物塑料。

Titanic Design created this in-house piece to display their 3D printing skills.

泰坦尼克设计公司设计的作品印证了3D打印技术

“I claim signage has some art to it,” Price said. Surrounding the logo element of the sign are functioning gears, which show off 3D printing capabilities, but are also a way for the Titanic team to test how well 3D-printed parts can hold up over time. The sign was hung in late 2018, and so far, so good.

普赖斯说:“我认为标识有一定的艺术价值。我们这次把齿轮元素加入到3D打印中,这展示了3D打印能力,也是泰坦尼克团队测试3D打印部件随着时间的推移可以保持多久的一种方式。这个标识是在2018年末悬挂的,到目前为止,一切很好。”

What does 3D printing mean for the business of visual communication? Price reiterated his mantra that 3D printing is just “another tool in the toolbox. We by no means would say you should 3D print everything. You’re always going to have areas [in which] 3D printing can never compete – and I say that as a 3D printer,” he said. Titanic often collaborates with other fabricators, and Price added that traditional methods are still irreplaceable in many ways.

3D打印对于视觉传达行业意味着什么?即3D打印只是“工具中的另一个工具”。我们绝对不会说你应该用3D打印机打印一切。你总会有3D打印永远无法竞争的领域。泰坦尼克团队经常与其他制造商合作,普莱斯补充说:“传统标识在很多方面仍然是不可替代的。”