APPLE CO-FOUNDER Steve Jobs once said, "I have great respect Afor incremental improvement... but I've always been attracted to the more revolutionary changes." His outlook lends to the reason why over 90 million people own an iPhone. To change an industry takes vision, fortitude and execution. It takes knowing what technology is currently in place and building on it to provide a better solution. Change for the better relies on a series of improvements to ultimately trigger revolutionary over haul. And such a movement has occurred in the sign industry.

苹果联合创始人Steve Jobs曾经说过:“我非常尊重进步,同样具有革命性的变化会更吸引我。”Steve Jobs解释为什么超过9000万人拥有iPhone说:“因为这是是一个行业有远见、毅力和执行力的改变,包括了解当前的技术,并在其基础上构建,以提供更好的解决方案,所以发生了实质性的变革,让苹果发展的更好。”现在,标识行业也在发生着这样的变化。

Before the LED took over as the most popular option to light a sign, there were bulbs and florescent options. Wher sign makers-as well as members of other industries-real ized the efficiency of LEDs (along with their small size anc long life), they began including them in many more projects.

在LED成为最受欢迎的标识灯之前,有灯泡和荧光灯,直到标识制作者以及其他行业的成员真正发现了LED的优点时,如尺寸小、寿命长,他们开始将LED运用在更多的项目中。

According to Leslie Donels, Sales Manager at GOQ LED America, "Lower prices, higher quality and better viewing angles" all contribute to the reason for the rise of LEDs in sign projects. On top of that, LEDs have sparked change in other areas of the industry.

根据GoQ LED美国公司销售经理Leslie Donels的说法,“更低的价格、更高的质量和更好的视角”都有助于LED在标识项目中的增长。除此之外,LED还引发了该行业其他领域的变化。

Let's take a look at some specific advancements that have been made in LED technology, and how sign makers have modernized lighted signage through the years.

让我们来看看LED技术的一些具体进步,以及标识制造商多年来如何让照明标识更现代化。

Today Versus Yesterday

今昔对比

It's been documented that LEDs have surpassed other lighting methods in signage as the preferred choice. However even over the last five years, there have been frequent improvements to LEDs.

据报道,LED不仅是发光标识首选的材料,还已经超过了其他照明方法。另外,在过去的五年里,LED也有了频繁的改进。

“LEDs have continued to improve in efficiency over the past five years," tells Gray Lankford, Distribution Sales Representative, GENLED Brands. "We've also seen colon binning yields tighten, allowing the cost to decrease as more of the visibly acceptable product yield can be utilized."

GENLED品牌分销销售代表格Gray Lankford表示:“虽然过去5年,led的效率不断提高。但是我们看到,随着更多明显可接受的产品产量的利用,LED标识产量也在扩大,从而降低成本。”

Haitz's Law has dictated that costs will continue to fall as LED quality increases (See Page 19). This is the number one ceason why LEDs are trusted and used more frequently today than ever before.

并且海茨的法律规定,随着LED质量的提高,成本将继续下降。这就是为什么LED在今天比以往任何时候都更受信任和使用频率的头号原因。

"Efficacy has increased to a point where LEDs can beat pretty much any other normal lighting technology in terms of lumens per watt," says Mike Bluhm, Director of Global Product Solutions at SloanLED. "This results in lower energy costs, and fixture costs decrease since you need fewer LEDs for the same number of lumens. You can also reduce the heatsink size since you're gen erating less heat. Quality of light has steadily improved to where LEDs can rival or outperform most other light sources."

SloanLED全球产品解决方案主管Mike Bluhm表示:“就每瓦的照明而言,LED的效能已经提高到几乎可以击败任何其他常规照明技术的水平。这就降低了能源成本,而且固定装置的成本也降低了,因为相同照明的LED需要更少。你也可以减少散热器的大小,因为你产生的热量会更少。LED光源的发光质量已经稳步提高,可以与大多数其他光源竞争,甚至超过它们。”

To add, "less modules are required to light a larger area and less work (is needed) for installation," explains Donels. This meaa that sign shops can also save money on labor costs while customers reap the benefits of a high-performance sign.

要补充的是,Leslie Donels解释道:“更大面积的照明需要更少的模块,而使用LED安装所需的工作量很少。”因此,LED不仅让标识商节省人力成本,同时还会让客户获得高性能标识的好处。

Blunm reinforces this concept by sharing that, "The increased efficacy in combination with lenses allow the user to install less product. Less product means less labor cost, thus easier to use."

Mike Bluhm也强调了这一概念,他说:“与镜片结合使用,提高了效率的同时,用户也可以安装更多的产品。产品安装时间越少意味着劳动力成本越低,因此更容易使用。”

“As efficiencies have increased, fixtures and modules with lower power and greater lumen output have been designed," Lankford says. "Therefore, we can have fewer fixtures or modules used in lighting our signs."

Gray Lankford也说:“随着LED光源效率的提高,设计出了功率更低、照明输出更大的夹具和模块。因此,我们可以减少用于照明标识的灯具或模块。”

In the past, sign makers were cautious about, not only how many LEDS were used, but also where they were placed. Hot spots and shadows caused problems with uniform illumination and made the sign appear less than professional. Today, high-performance LEDs can make up for poor placement "Due to the proliferation of using optics in signage LED prod ucts, the exact placement of the product is not as critical as it once was," explains Bluhm. "Shadows and light separation from sharpa corners in signs have been dramatically reduced by these optics which move the light sideways versus straight up.

以前的时候,标识制作者对使用LED的数量和放置位置都很谨慎。热点和阴影常常造成照明不均匀的问题,使标识显得不专业。如今,高性能LED可以弥补放置不当的问题,Mike Bluhm解释说:“由于在标牌LED产品中使用光学器件的增多,产品的准确放置不像以前那样重要。”通过这些将光线从侧面移动而不是直接向上移动的光学装置,标识中的阴影和光线分离已经显著减少。

This "less is more" benefit presents a true cost savings without sacrificing quality.

这种“少即是多”的好处可以在不牺牲质量的情况下实现真正的成本节约。

Welcoming Change

欢迎变革

One of the biggest transformations in LEDs has been the ability to move the light in a way that improves quality, as Bluhm mentioned. It is one mprovement that has added value to the entire sign.

正如Mike Bluhm所提到的那样,LED最大的转变之一就是能够以提高质量的方式移动光线,这是一项对整个标识行业有附加价值的改进。

"With greater lumens in smaller packages, we are tasked to develop lenses that can maximize each module's utility by spreading the light wider, continuing to minimize the number of modules required to light a sign," Lankford says. "The most difficult area for this is in channel letters where we must still account of the bends and turns, limiting the effectiveness of lens technology."

Gray Lankford表示:“我们的任务是在更小的包装中使用更大的流明,在透镜的基础上,通过将光传播得更宽,从而最大限度地发挥每个模块的效用,继续减少照明标识所需的模块数量。这方面最困难的是在发光字母中,我们仍然必须考虑弯曲和转弯,限制透镜技术的有效性。”

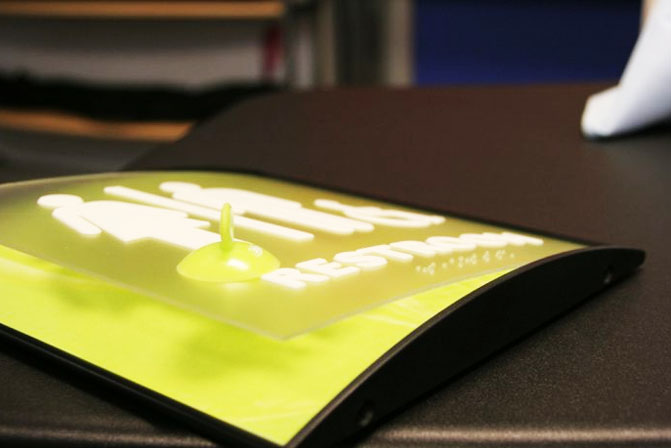

In the past, sign makers typically adhered to building a channel letter with a five- to six-inch depth. LED advancements have allowed sign mak ers to create even thinner letters.

在过去,标识制作商通常坚持用5到6英寸深的凹槽字母。<span style="color: rgb(0, 0, 0); font-family: 宋体; font-size: 11pt; mso-spacerun: "yes"; mso